Solutions

MES-EBR

GxP Intelligent Manufacturing

Becolve Digital’s MES | EBR is a modular and scalable solution for the digitization, execution, and reporting of manufacturing guides comprehensively. This solution is designed to meet the specific needs of the regulated industry, offering modules that adapt to each particular case, optimizing resources and eliminating unnecessary costs.

MES | EBR as a response to the challenges of the sector

As its name indicates, Becolve Digital’s MES | EBR solution integrates an EBR module within the MES system. Thus, it offers its users:

- All the functionalities of a manufacturing execution and operations management system.

- The functionalities that characterize an EBR module, such as the digitization of manufacturing guides, guided manufacturing, electronic records, and the equipment Logbook.

The DNA of our MES | EBR

Connects manufacturing guides with real-time data and allows the capture of production values, ensuring step-by-step execution aligned with the actual state of the plant.

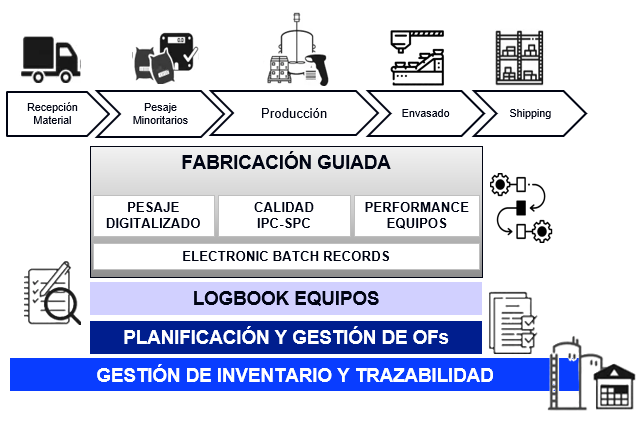

Includes planning-sequencing and production WO management, management of inventory, IPC-SPC quality, weighing of minor components, equipment performance, and Logbook, covering the entire manufacturing process from the reception of materials to Shipping.

Allows the detailed recording of each step of the production process, as well as the parameters, events, and variables of relevant GxP processes and embedded reporting, being a comprehensive solution for the monitoring and auditing of each manufacturing batch.

Main functionalities of the solution

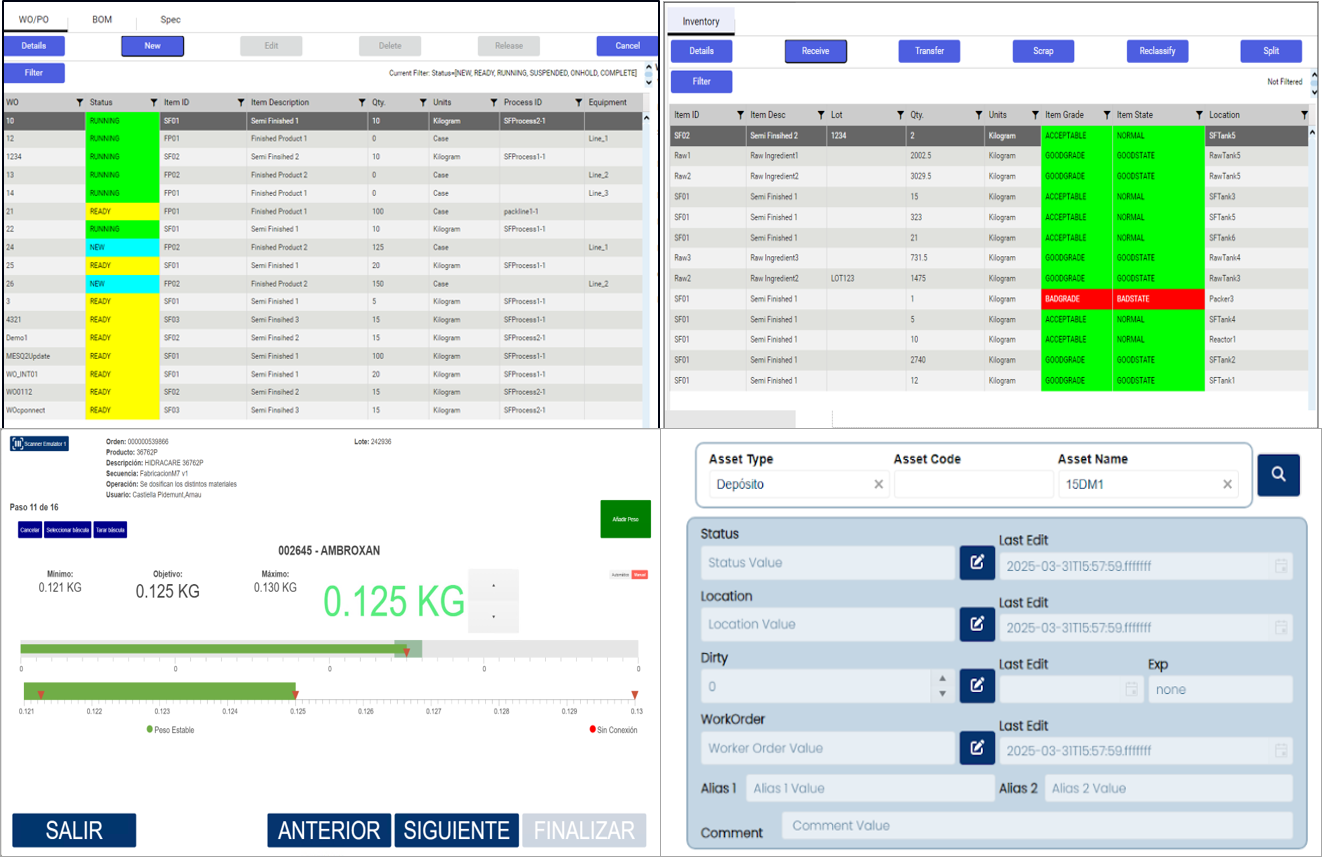

The solution digitizes manufacturing guides adapting to different formats and structures, eliminating the use of paper and ensuring security, traceability, and control over production procedures.

This includes native integration with SCADA-IIoT and Batch, digitized weighing of minor components, automatic and/or manual IPC-SPC quality controls, integrated business logic, optimization of equipment performance, and electronic batch record (eBR).

The MES | EBR allows to electronically record interventions in equipment such as cleaning, calibrations, states, conditions of use, and maintenance. It ensures the correct execution of procedures, prolonging the useful life of the equipment and facilitating audits and regulatory compliance.

Offers optimized planning synchronized with the operational reality of the plant, allowing the management of manufacturing orders (WOs) in real time to improve efficiency and response to production changes.

Manages inventory and material traceability throughout the entire manufacturing process, from the reception of raw materials to the shipment of the finished product, ensuring continuous visibility and control.

It is capable of integrating with third-party systems such as LIMS, ERP, BMS, SCADA, GMAO, and laboratory equipment, scales, or readers, ensuring total interoperability and integrated information management.

How is the value of MES | EBR manifested?

Quality, safety, and control from step 0

Digitizes manufacturing guides (MBR), with guided execution and real-time recording of variables throughout the process, ensuring alignment with the plant and avoiding errors.

Records ready for any audit

Reduces errors and review times thanks to the EBR, allowing complete traceability and regulatory compliance.

Subtracts errors, adds traceability

Avoids errors and production losses through the digitization of events and equipment records.

Your raw materials and products, connected and synchronized

Improves reception, inventory control, expirations, and weighing with integration of equipment such as scales and code readers.

Monitor, adjust, and improve, in a loop

Facilitates control and continuous improvement, boosting efficiency and operational productivity.

Preparation for any unforeseen event

Allows responding to changes in demand, deliveries, formats, or short series, aligning theoretical planning with actual execution.

Solution ready to scale

Allows growing in a structured way with unified communications and real-time monitoring.

Contact an Expert

Fill in your information and we’ll contact you.