How to Enhance Situational Awareness in HMI/SCADA

Increasingly, companies are looking to improve their systems to stay up-to-date, especially SCADA/HMI. Given this, there is no alternative but to establish standards for managing data and equipment.

Increasingly, companies are looking to improve their systems to stay up-to-date, especially in the case of human-machine (HMI) SCADA applications used to control and operate in industrial plants.

Operations managers are incorporating various software solutions into existing ecosystems, with the goal of increasing business value and security through minimal investments. However, with the rise of process automation solutions in factories, companies have fewer human resources, and the few that exist must be responsible for complex operations.

Given this scenario, there is no alternative but to establish standards for managing data and equipment. Companies must understand the importance of Situational Awareness and task automation, in addition to adopting a results-oriented approach to operations control.

Results-oriented Approach – Design for Users

Most current HMI applications only display information, sometimes too much, which operators then process in one way or another depending on their level of experience. In this context, there are considerations to take into account to improve the particular results of each company.

While goal-oriented design focuses on improving overall safety and profitability, techniques such as structuring the visualization of windows in the HMI, the appropriate use of color, effective alarm management, and the proper design of visual elements provide a specific context for each user role.

An operator will respond more effectively if they access information in a clear and orderly manner.

Structuring the Visualization of Windows

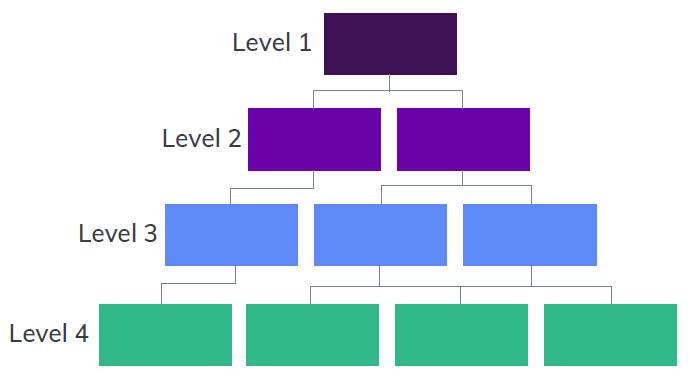

There is a hierarchical model, consisting of four levels, to effectively guide the user towards awareness, action, or details depending on the window level.

- Level 1:

Level 1 windows are essential to increase operator awareness, as well as to determine when an action or investigation is required. They are similar to an information panel.

- Level 2:

Level 2 windows provide an overview of the entire facility for operations personnel to take the necessary actions or investigations. These windows may contain elements associated with the process, although they are not expected to present all the details.

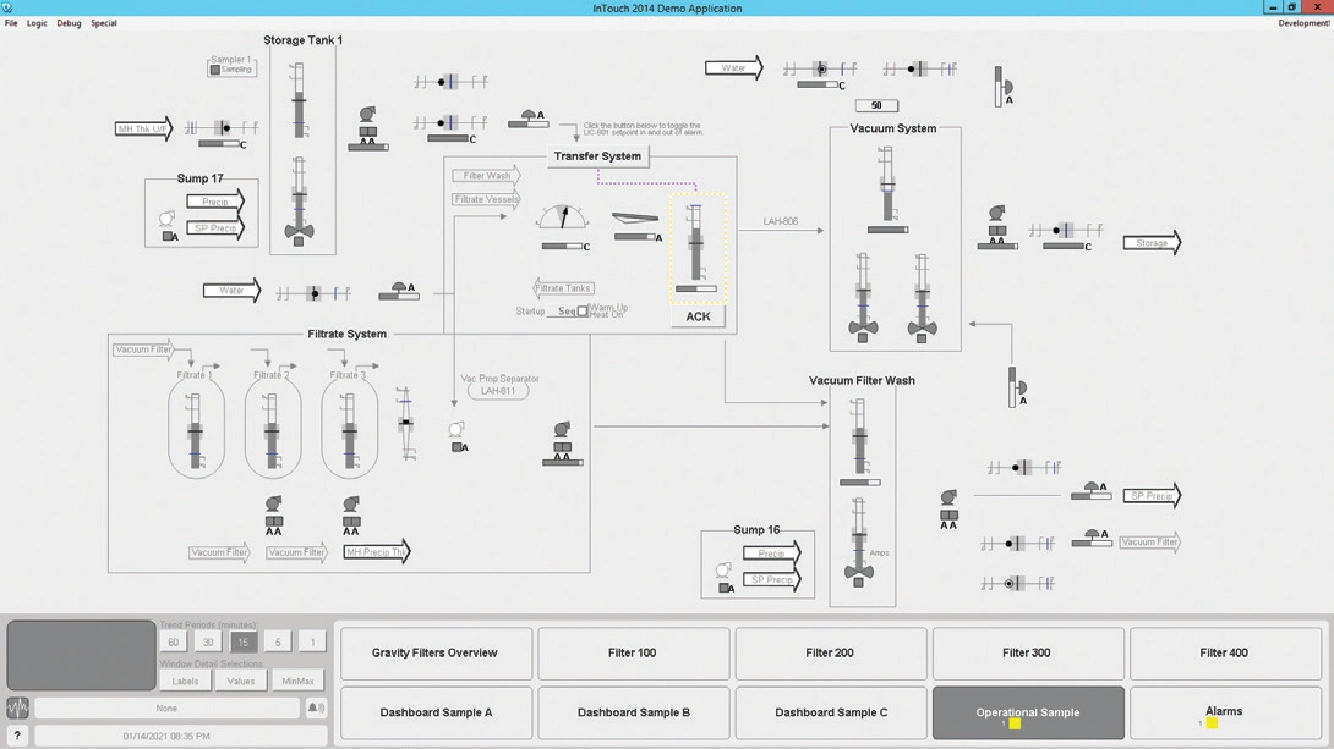

- Level 3:

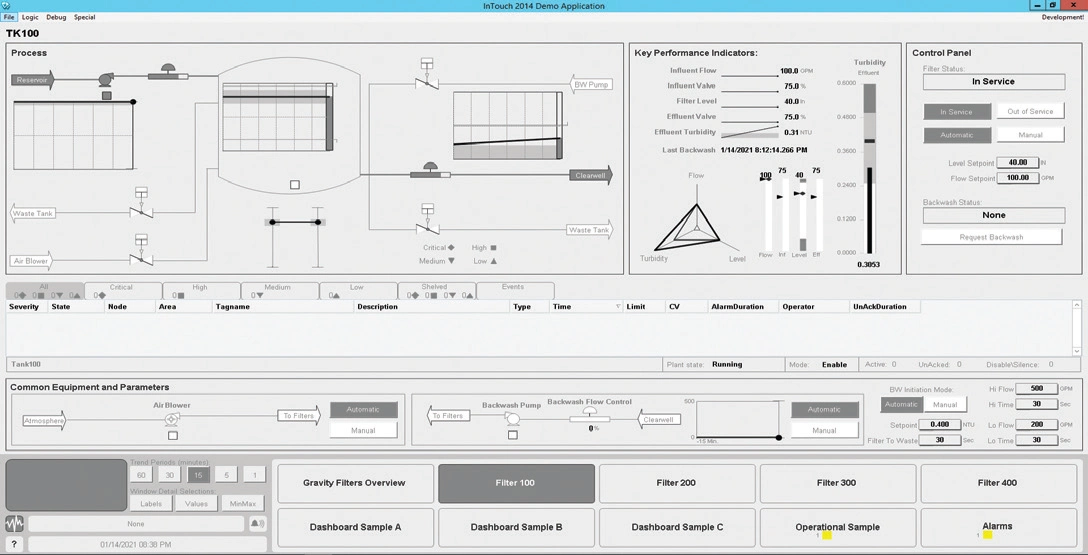

Level 3 windows, very similar to the piping and instrumentation diagrams (P&ID) of most systems, are used with the support of level 2 screens. They provide access to the status of the equipment for all those within the scope of the associated level 2 screen.

- Level 4:

These last ones provide auxiliary information, such as trend analysis, events or alarms; adjustment of loops, help/procedure information, and so on. There may be more than one level 4 window for each level 3 screen. This technique can improve the success and efficiency of extensive procedures.

Use of Color and Animation

Initially, due to the limitations of computers at that time, HMIs had very basic graphics. As technology improved, these applications began to focus more and more on operator efficiency.

The same engineers in charge of developing the system initially designed the screens with graphics that were too complex, flashy, and very colorful, without taking into account that the end user had a different profile and different objectives. Over time, they realized the importance of establishing and strictly using color standards to achieve an optimal HMI design.

Effective Design Elements

In addition, to be effective in the design of an HMI SCADA, graphics must be standardized throughout the application. These elements are symbols or screens optimized so that communication is more direct with the minimum load of information: only the necessary one.

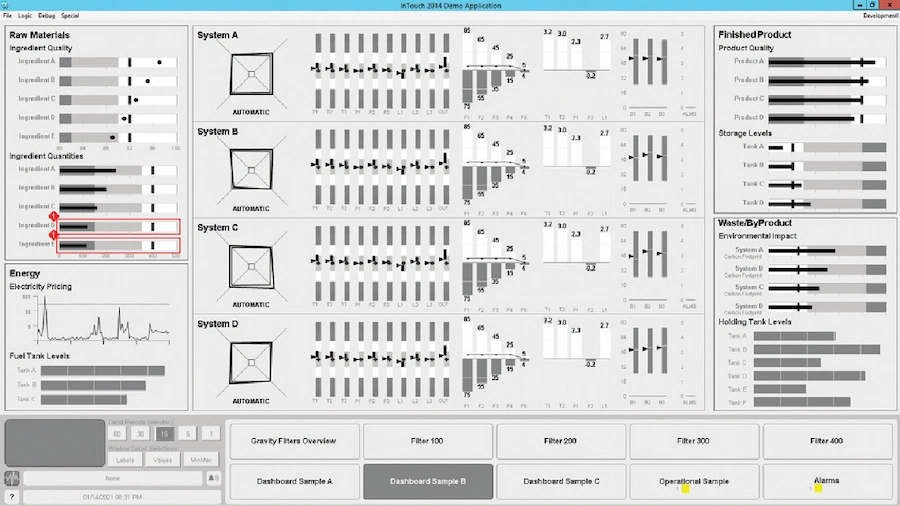

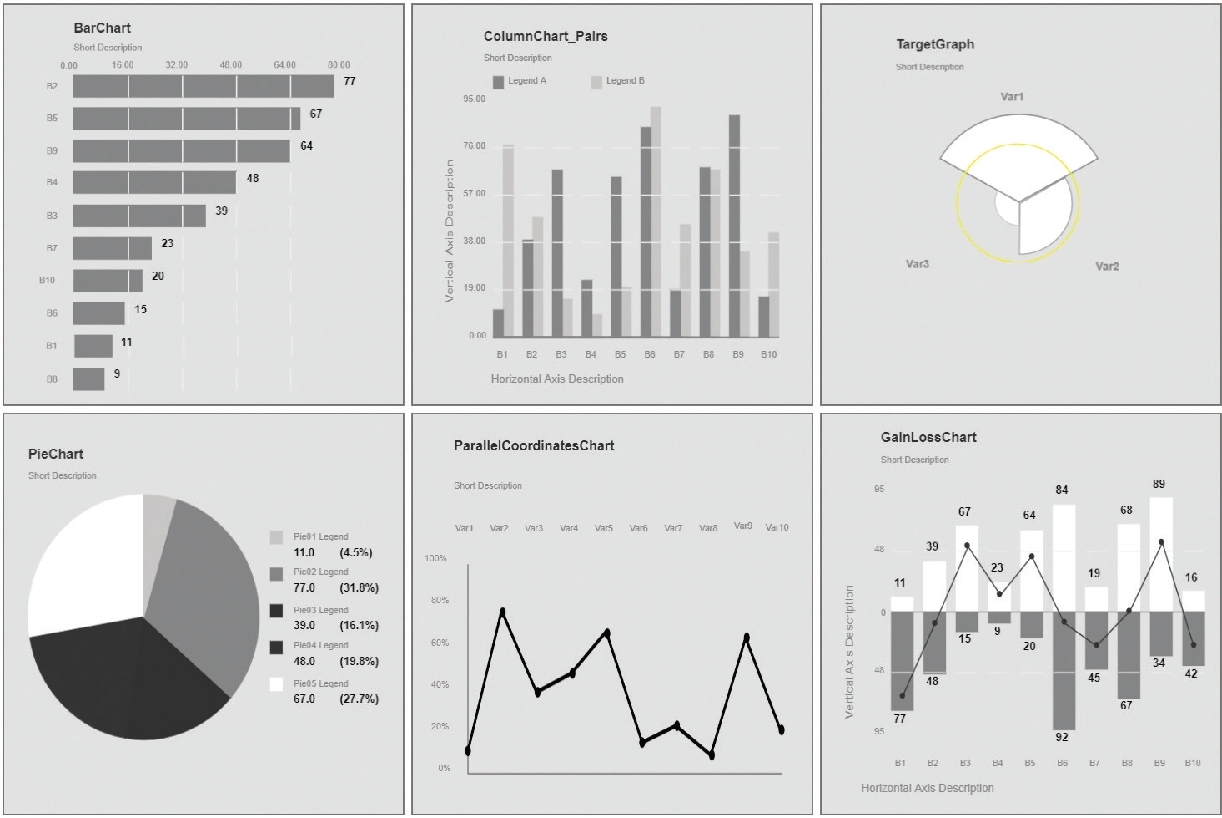

Meters with Trends: Dashboard Tools

Graphs with trend visualization provide more value to operators so that they can analyze appropriate actions in the future. For example, the visualization of a control loop of a process with this format will provide great value to the operator, as a trend is represented over time and not only the configuration parameters of the P&ID control.

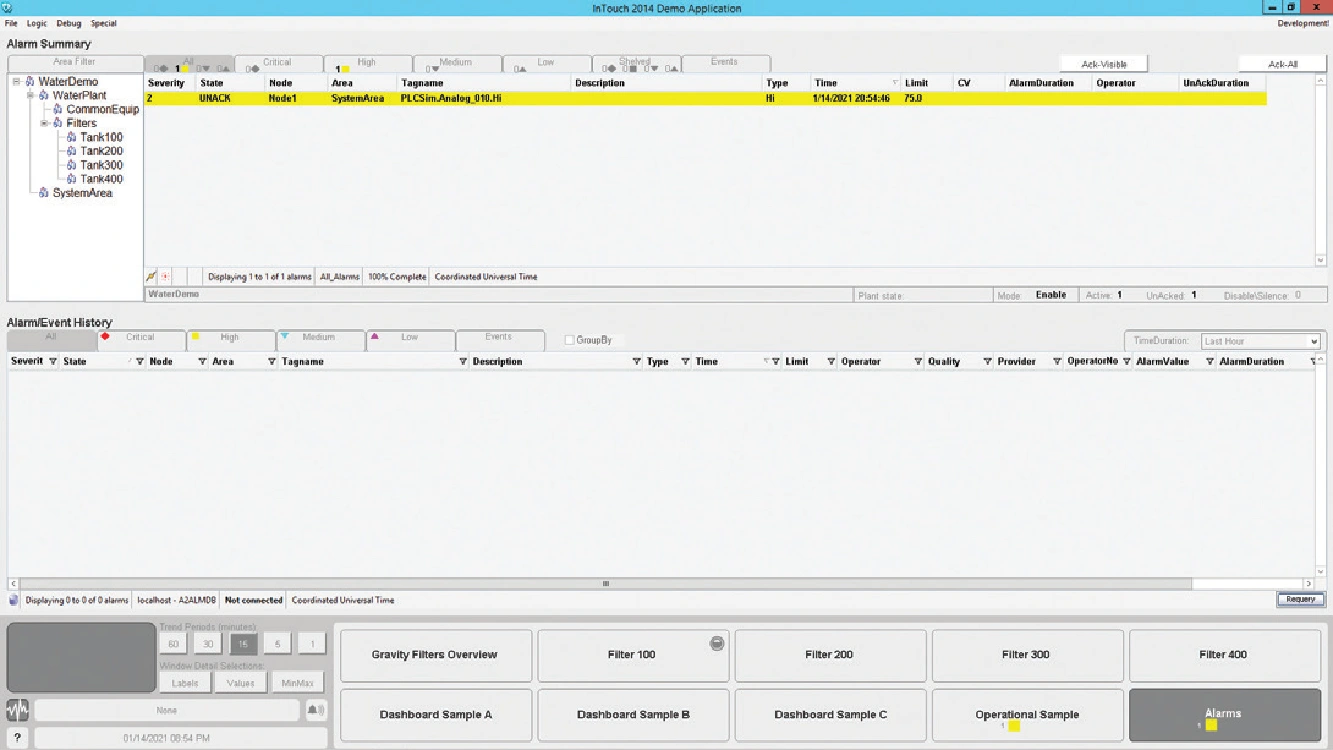

Alarm Management

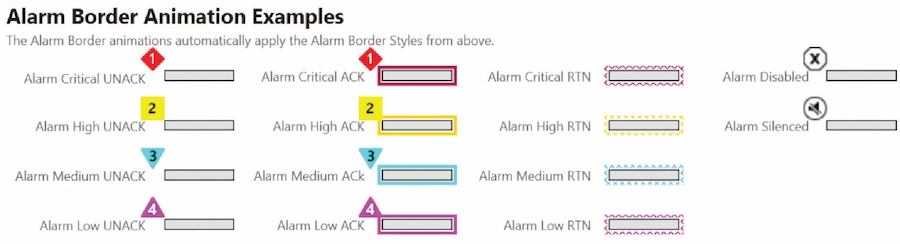

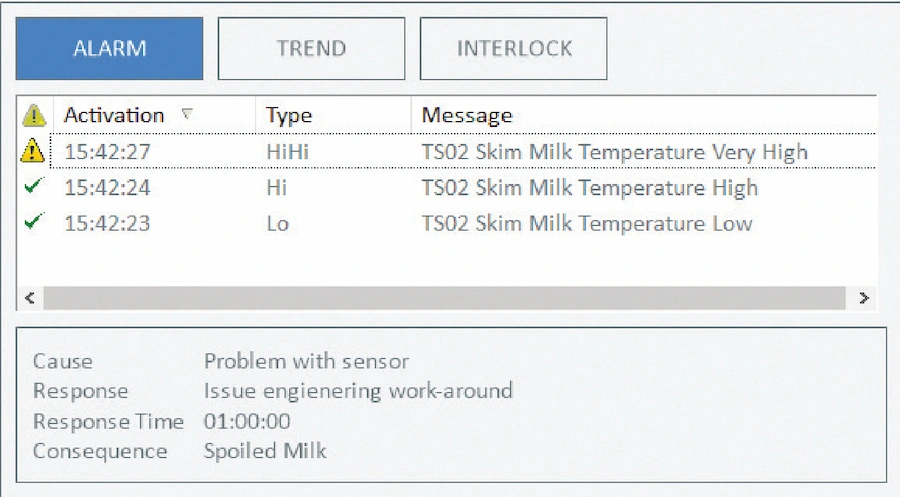

Although alarms are crucial to drive operator actions, the vast majority of systems generate a large volume of alarms that professionals cannot handle and, therefore, stop paying attention to them. In order to improve the management of these, they must be categorized according to their severity in levels: critical, high, medium and low. These severities define the maximum response time.

In addition, alarms should only be activated when an operator action is required; the rest should be considered simple notices to support the information.

An important support is the use of Alarm Border, which at a glance helps to identify which alarms require action.

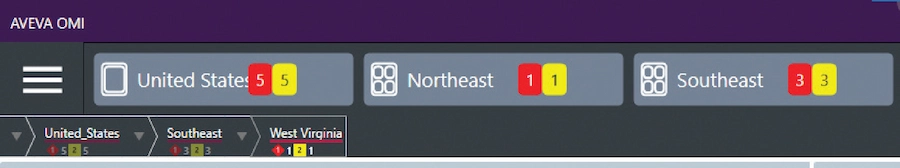

Aggregation of alarms

In the design of the HMI, alarm messages are often used to show the most recent ones, in duplicate, which can hide those of greater severity. Aggregating alarms in a hierarchical manner, similar to the navigation structure, allows the overall states of the alarms to be visually displayed as indicators in the navigation element. Thanks to this, operators can easily access the associated graph.

Cause and action of alarms

Automation and staffing problems hinder the operator’s experience, especially in systems with many alarms. Inexperienced operators may focus on the consequences rather than the root causes, which delays the necessary actions. A small annotation next to the alarms could help operators act more effectively, by receiving the possible causes of the alarms, the recommended responses, and the potential consequences.

In short, modern industrial systems require a new approach to process visualization due to their evolution, increasing automation, staffing problems, and remote operation. An approach based on Situational Awareness will improve the probability that an industrial process reaches its business objective, empowering operations personnel.

Con la solución de Becolve Digital puedes establecer estándares para gestionar los datos y equipos y mejorar el día a día de tus operadores.