Industrial Data Management: Fundamentals for Efficiency and Decision-Making

Efficient management of industrial data is crucial to optimize processes, increase productivity, and facilitate more informed and accurate decision-making. Learn how to achieve it.

Industrial Data: a Resource that Has Evolved from Useful to Indispensable

In the not-so-distant past, writing down what happened in the production plant in a notebook was the way to avoid working blindly and have the basic information recorded somewhere. Today, with the number of tools available for collecting information, industrial data has become a fundamental strategic resource.

Provided, of Course, that it is Managed Correctly.

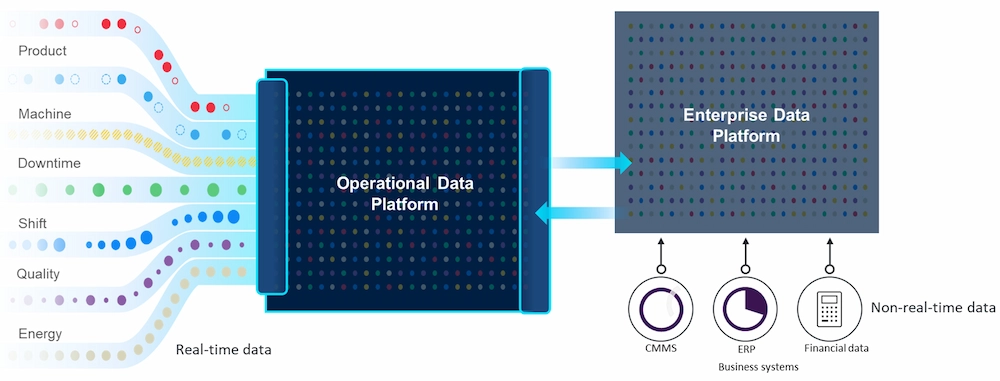

Efficient management of this data is equivalent to optimizing processes, increasing productivity, and, most importantly, facilitating more informed and accurate decision-making. But the fact that they are often scattered across multiple sources represents a significant challenge for companies, especially with the increase in sensors, distributed systems, and the geographical dispersion of operations. Therefore, it is essential to implement strategies and technologies that guarantee cohesion and efficient access to all information in real time.

A clear example of this challenge is found in predictive maintenance. Although it has the potential to optimize maintenance costs, reduce downtime, and extend the useful life of equipment, its effective implementation faces obstacles related to the quality, quantity, integration, and security of the data.

Fortunately, these difficulties do not prevent solving the so-called “data problem.” To do this, however, it is necessary to invest in solid data infrastructures that facilitate the acquisition of information from various sources, allowing the standardization, organization, transformation, and contextualization of the data. In this way, in addition to minimizing obstacles, the benefits of any initiative aimed at operations and business analytics are maximized.

So, What is the Best Strategy for Managing Large Volumes of Industrial Information?

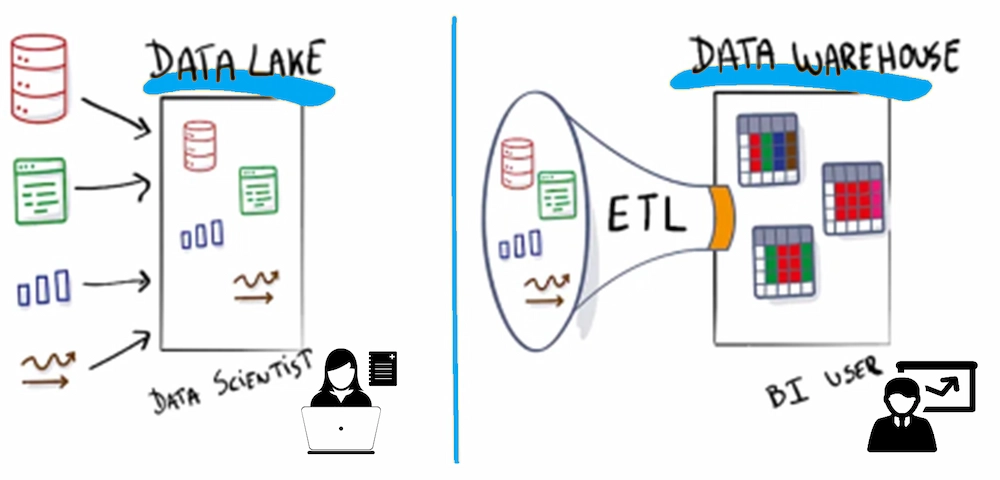

When considering the management of large volumes of data, several technological options arise that adapt to different needs and objectives of organizations. Among the most prominent are Data Lakes and Data Warehouses, two approaches that offer different ways to store and organize information.

But it doesn’t end there. The idea of a Data Ocean, more conceptual than technical, makes us rethink whether we should broaden our perspective towards comprehensive data management systems.

At the same time, there is a debate about whether these systems should operate under the perspective of the world of technological operations (OT), closer to the infrastructure and industrial processes, or IT, oriented towards information management. Or perhaps a hybrid approach would be the most appropriate to integrate the best of both worlds? These questions invite us to reflect on what is the best strategy to manage the growing amount of data in our organizations.

Likewise, the possibility of implementing a Data Platform that encompasses these concepts is increasingly attractive to many companies. Let’s see why:

Towards an OT Data Platform

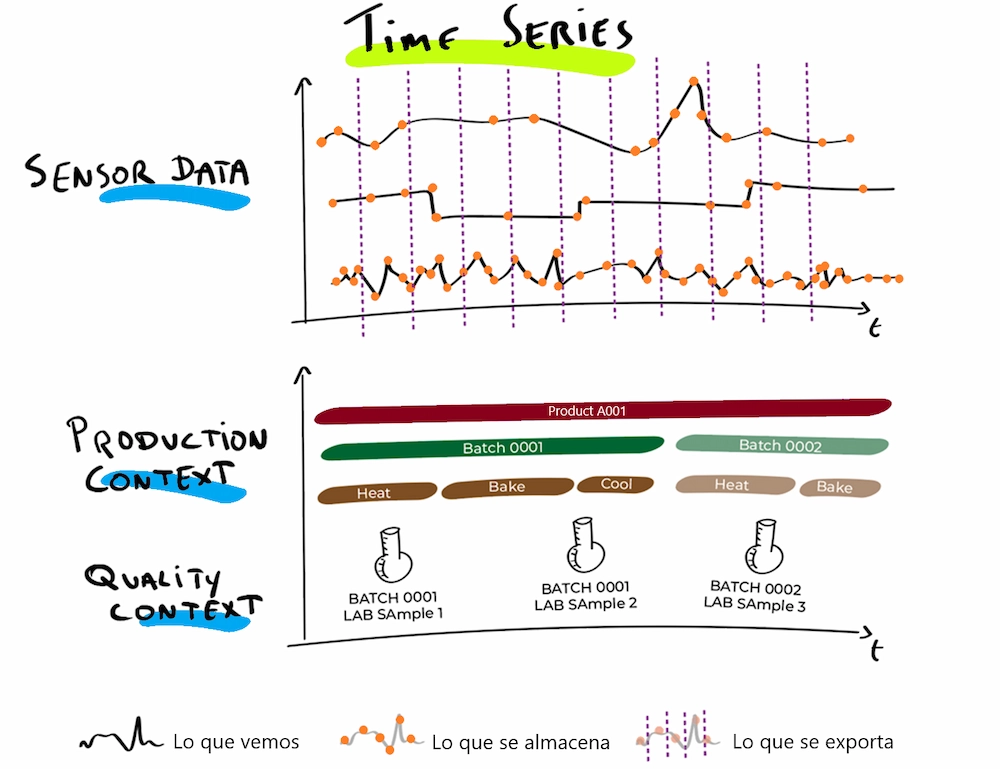

Control systems in industrial environments are designed to capture and store data from sensors that monitor equipment and processes. This data, known as time series, reflects in real time the behavior of machines and operations, thus being crucial for operational analysis.

In most cases, they are stored in systems called historians, designed to write and read data at high speed. They are extremely efficient systems for managing large volumes of raw data, captured directly from the sensors but without applying structured schemes, which makes them similar to a data lake in an IT environment but in a local context and specialized in industrial operations.

Despite their efficiency, they have important limitations. To begin with, by storing data mainly from sensors, they leave out other essential aspects such as quality, production, or equipment maintenance reports. This makes them only one of the multiple data sources that must be integrated to perform complete analyses and generate reports that provide real value to the decision-making process.

In addition, to get the most out of time series data, it is essential to contextualize it (that is, give it meaning within the OT environment) to link sensor data with other critical factors that surround it and thereby improve the capacity for analysis and understanding.

There are several types of relevant contexts in an industrial environment:

- Asset context: allows you to relate the data to the physical assets or machines in the plant, providing a clear view of which equipment is generating the data and how they behave over time.

- Temporal context: defines the exact moment when a measurement or event occurred, which is crucial for analyzing trends, identifying patterns, and correlating data with external events or specific operating conditions.

- Production context: it is possible to link the data to the specific manufacturing processes that are occurring. This type of context, which is generally found in a Manufacturing Execution System (MES), connects sensor measurements with the actual production flow, allowing a better understanding of the performance and efficiency of the process.

- Maintenance context: relates the data to the equipment maintenance programs, which facilitates a more detailed analysis of the operational efficiency of the equipment (OEE) and the identification of possible problems or areas for improvement.

- Quality context: linking product quality with the parameters of the production process is essential to improve the consistency of the final product. This context allows you to identify correlations between operating conditions and quality deviations, which facilitates real-time adjustments to maintain the desired standards.

In addition to these contexts, there may be others that provide value, such as financial, security, regulatory compliance, or even environmental context. Incorporating them into an OT data platform and linking it with the IT counterpart will allow us, beyond better managing the data, to give them a broader and more useful meaning for real-time decision-making.

In short, moving towards a data platform in OT that integrates multiple contexts is key to transforming the industrial environment. Only in this way will we be able to optimize processes, improve operational efficiency, and respond agilely to the changing needs of the market and the industry.