What is an MES-EBR and why is it so Key in Regulated Environments?

Intelligent digitalization for regulated environments: discover the solution that translates into efficiency, traceability, and compliance

Regulated industries such as pharmaceuticals or chemicals require guaranteeing the quality, “repeatability,” and safety of production above productivity, in addition to documenting the entire production process due to the existence of audits and strict regulations. In this context, the use of paper and the lack of digitalization generate multiple operational challenges that impact efficiency, traceability, and regulatory compliance.

Common Challenges in Regulated Environments

Let’s get down to business: despite the level of regulatory requirements, it is common to find factories where key processes are still manual. This creates a series of obstacles:

- Errors in the production process due to the use of paper in manufacturing guides.

- Quality, repeatability, safety, and traceability problems in operations.

- Inefficiency in the review of manufacturing processes due to dependence on manual documentation.

- Lack of traceability of production events, maintenance, and process variables in equipment.

- Absence of digitized quality controls, both automatic and manual.

- Inefficient management of raw materials and products in critical phases such as receiving, weighing, and production.

- Difficulty complying with regulations such as GxP, FDA 21 CFR Part 11 & EU Annex 11.

- Low productive efficiency of equipment.

Addressing this set of needs requires adopting a strategic vision focused on optimizing production management for regulated environments, without compromising the safety or quality of the final product. To this end, a modular and scalable MES-EBR solution is positioned as the indicated option to drive the digital evolution of the entire manufacturing process.

But Exactly, What is an MES-EBR?

A MES-EBR solution, as its name suggests, is defined from the integration of the EBR module within the MES system:

- Benefiting from all the functionalities of a manufacturing execution and operations management system.

- Adding the typical functionalities of the EBR module such as the digitalization of manufacturing guides, guided manufacturing, electronic manufacturing records, and the equipment Logbook.

Becolve’s MES-EBR solution is modular and scalable, allowing the digitalization, execution, and reporting of manufacturing guides in an integral way. Likewise, it is designed to respond to the specific needs of the regulated industry, integrating specific modules according to needs, optimizing resources, and eliminating unnecessary costs.

How Does it Do it?

- Connects manufacturing guides with real-time data and allows the capture of production values, ensuring step-by-step execution aligned with the actual state of the plant.

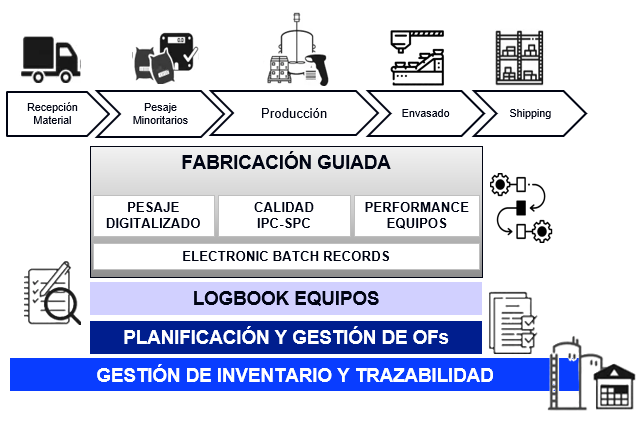

- It includes planning-sequencing and management of production work orders, production, inventory management of the entire manufacturing process, IPC-SPC quality, weighing of minor components, equipment performance, and Logbook, covering the entire manufacturing process from material receipt to shipping.

- In addition, it allows the detailed recording of each step of the production process, as well as the parameters, events, and variables of relevant GxP processes and embedded reporting, offering a comprehensive EBR solution for the monitoring and auditing of each manufacturing batch.

Main Functionalities of the MES-EBR Solution:

- Automated digitalization of On Premise manufacturing guidesBecolve’s MES-EBR solution has algorithms and models for digitizing paper manufacturing guides that adapt to multiple formats and data structures, offering an On Premise solution without the need to use cloud solutions, and providing security and protection of internal know-how.

- Advanced guided manufacturing, which includes:

- Native integration with SCADA-IIoT and Batch for:

- Connect manufacturing guides with real-time data and allow the capture of production values, ensuring an execution aligned with the real state of the plant.

- Unify production and process control, allowing to start and monitor productions in SCADA-IIoT and Batch.

- Digitized weighing of minor components that drives agility in material management, avoiding errors and ensuring quality in production.

- Easy integration of equipment (scales, printers, barcode readers…), for the digitalization and improvement of material management and the production process.

- Quality controls IPC (inProcessControl) automatic and/or manual and advanced statistical controls SPC to ensure compliance with production standards.

- Business logic integrated in the manufacturing guides to adapt the technology to the needs of the organization.

- Optimization of equipment performance to boost its performance, availability, and productivity.

- Electronic batch record (eBR) of each step of the production process, as well as the parameters, events, and variables of relevant GxP processes, together with embedded reporting, for the monitoring and auditing of each manufacturing batch.

- Equipment Logbook

Equipment logbook to ensure the correct execution of procedures and ensure quality in batch manufacturing. This module allows optimizing maintenance, prolonging the useful life of equipment, reducing operating costs, and streamlining audits and regulatory compliance. And all this, thanks to a system of electronic recording and traceability of interventions in equipment such as containers, scales, or production machinery.

Among the registered interventions are cleanings, calibrations, equipment statuses, utilization (people and conditions), and maintenance.

- Optimized production planning and synchronized with the reality of the plant and real-time work order management.

- Inventory management and traceability of materials throughout the manufacturing process (from receipt to shipment).

- Communication with 3rd party systems: LIMS, ERP, BMS, SCADA systems, CMMS, laboratory equipment, scales, readers, etc.

How Do Organizations Benefit from Becolve’s MES-EBR Solution?

- Guarantees the quality, repeatability, safety, and total traceability of the production process, through the digitalization of manufacturing guides (MBR) and a step-by-step guided execution, with real-time recording of process variables. This ensures constant alignment with the real state of the plant, preserves data integrity, and avoids errors during production.

- Allows the monitoring and auditing of manufactured batches through electronic records (EBR), eliminating errors derived from the use of paper, reducing the review times of manufacturing processes, and ensuring regulatory compliance.

- Ensures the traceability of the status of equipment to avoid errors in production and minimize unplanned stops, thus reducing production losses. This is achieved through the digitalization of records of events related to equipment.

- Facilitates the efficient management of raw materials and products in the processes of receiving, production, inventory control, and expirations, through the digitalization of weighing, effective warehouse management, and integration with measurement and control equipment such as scales or barcode readers.

- Optimizes the performance and availability of equipment through the control and continuous improvement of productive efficiency.

- Allows adapting to changes in demand, delays in the delivery of raw materials, changes in format or production in short series, thanks to a theoretical production planning synchronized with the real execution.

- Facilitates technological standardization, in order to grow in a structured and orderly manner.

- Standardization of communications

- Real-time monitoring