Products

AVEVA Batch Management

AVEVA Batch Management effectively manages batch operations flexibly, for the multiple flows and products of process industries such as life sciences, fine chemicals, and food and beverage.

In addition to meeting ISA-88 standards for batch control, it provides guidance and supervision of recipe management and batch execution. It automates batch processes to deliver consistent quality to recipe specifications and genealogy for a complete batch history.

Customers using Batch Management reports better leverage assets, increase operational efficiency, and bring their new products to market sooner. Batch Management enables process engineers to create and modify recipes methodically and safely, maintaining compliance with internal and external regulations or safety requirements.

How does AVEVA Batch Management help you?

AVEVA Batch Management is a batch control application, independent of the control system, that can be used for the most complex batch processes that require a high level of flexibility.

Equipped with easy-to-use recipe configuration tools, process engineers can quickly create or change recipe procedures and formulas without the need for specialized knowledge or the underlying control systems.

Batch Management is unique in its process capability model, which goes beyond ISA-88 to include transfer phases. This allows the batch engine to manage flexible product batches, thus facilitating multi-product, multi-stream batch execution on shared equipment.

Built-in security and material management capabilities, including material consumption, movements, and stock levels, help provide a complete Electronic Batch Record (EBR) and reduce the cost of industrial regulatory compliance.

Features

Server versatility

- Coordinates concurrent batch execution on networked equipment and facilitates operator interaction.

- Manages batch execution either by direct connection to a control system or through integration into AVEVA System Platform.

- Multiple Batch Management Servers can be configured to share a single batch history database.

- Facilitates the deployment of solution architectures that meet the needs of critical and high-availability batch applications:

- Hot restart.

- Redundant option.

- Virtualization support.

Power for customers

- Offers remote client development and runtime applications, as well as .NET and ActiveX controls that can be easily integrated into the process graphic displays of both AVEVA InTouch HMI and InTouch OMI. This provides operators with an integrated user interface for the batch server.

- The remote equipment services edition is a cost-effective solution for applications that leverage centralized administration and maintenance of multiple Batch clients.

Intelligent interfaces

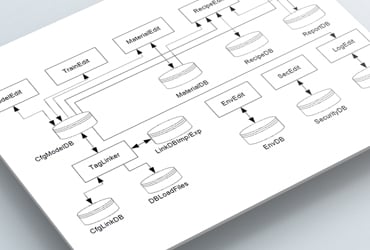

AVEVA Batch Management includes a set of programming tools for developing custom batch interface applications: it provides access to material and recipe databases, access to the batch function interface, extends Batch Manager capabilities, and enables integration into the enterprise.

Connectivity and open integration

- Provides connectivity for real-time communication to any control system or plant device through AVEVA Communication Drivers.

- Provides batch object templates for units, connections, segments, and phases, as well as a model import utility to automatically develop and synchronize the Batch Management process model in the AVEVA Application Server model.

- Batch Management execution information is available directly for use with other software, such as AVEVA Historian, AVEVA MES, and AVEVA Skelta BPM, as well as for integration with third-party systems.

- Batch Management Server supplies alarms to the AVEVA distributed alarm system and supplies events to AVEVA System Platform Event Services. Batch Management sends the event type and context data that can be used to perform external actions, such as triggering workflows with AVEVA Skelta BPM.

- For advanced analysis and reporting, AVEVA Intelligence Enterprise Manufacturing Intelligence software incorporates pre-configured dashboards, interactive reports, and a data model for Batch Management.

AVEVA Batch Management. Advanced modeling, simulation, batch execution, and integration features for a better batch

- MODEL

Equipped with easy-to-use recipe configuration tools, process engineers can quickly create or change recipe procedures and formulas without the need for specialized knowledge or the underlying control systems. - SIMULATE

Recipes can be simulated against a model of the process without writing a line of control code. - EXECUTE

Batch scheduling capabilities, sophisticated equipment arbitration, and concurrent batches maximize asset utilization and throughput in multi-product, multi-stream plant environments.

Learn more:

Get in Touch with an Expert

Fill in your information and we’ll contact you.