Discover what a Model-Driven approach is and why it could be the solution for the evolution of your plant.

Join us to explore how the standardization of MES and SCADA systems ensures greater scalability and long-term consistency.

Standardization of MES and SCADA Systems: the Path to the Factory of the Future

The constant and growing search for efficiency and competitiveness in companies, two attributes so indispensable for success, demands that there be a constant digital evolution in plants. Modern and standard MES and SCADA systems play a fundamental role in the automation of factories. Why?

Because customized and closed solutions, considered viable until recently, prevent reaching the expected level of maturity. Instead, a standard is needed that facilitates the interoperability and integration of all technologies, ensuring the consistency and quality of production processes. And in this sense, the standardization of MES and SCADA, in addition to reducing costs and simplifying maintenance, improves scalability and adaptability as companies grow or evolve.

Model-Driven Approach: Unique Standardization for each Plant

Faced with this highly sought-after standardization, one might ask: if the solutions leave personalization behind, how are they then able to listen to the particular needs of each business, or each production facility? Thanks to the Model Driven approach, based on the creation and use of models that represent the unique processes and capabilities of each plant within a company.

These models are used to adapt the standard templates of operations, data collection, and continuous improvement practices to the specific characteristics of each plant. In this way, although each plant has differences in its production processes and automation systems, all can follow the same procedures, which allows for standardization at the enterprise level.

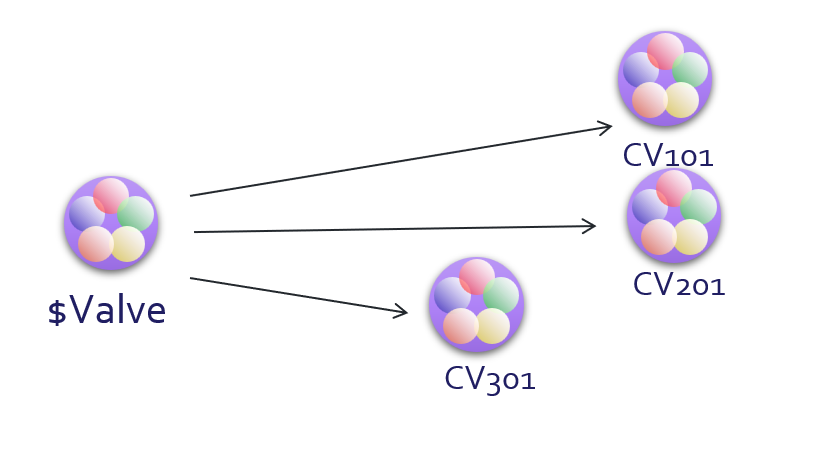

Thus, the Model-Driven approach allows defining standard models both at the level of monitoring and control of the plant (SCADA) and in the management of production (MES/MOM), working on three levels:

Definition of Standard Models: the Step by Step

First, data collection procedures are defined in the form of templates that abstract the differences in the production processes and automation systems specific to the plant.

Once defined, the information is passed to the system by creating templates for each item that is present in the plant, obtaining a digital representation of the plant model.

Subsequently, the same is done for the definition of production processes and the procedures that are present are digitized.

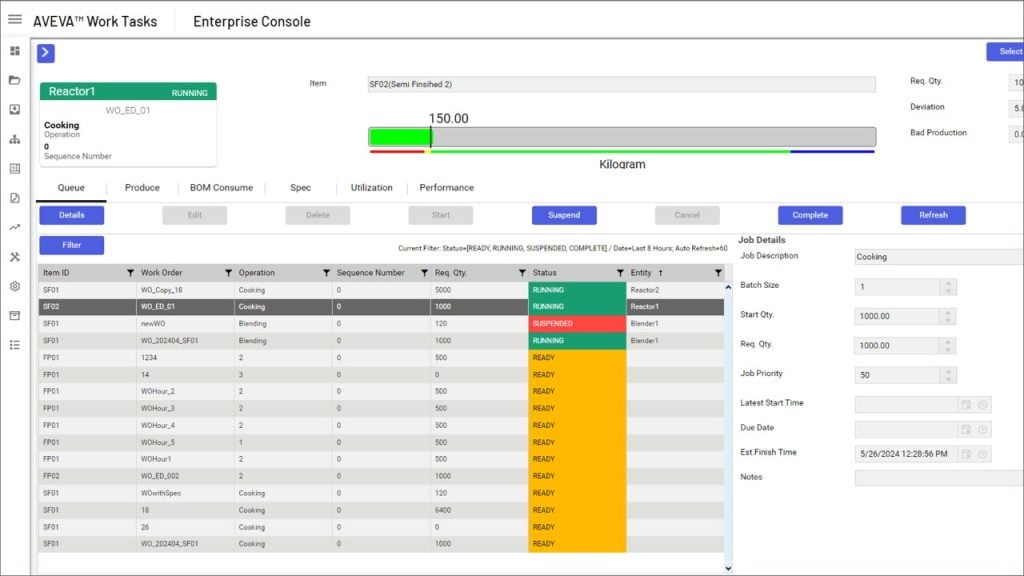

Once these standard models are determined, the visualization clients are adapted to each user profile, integrating all under the same application and maintaining a uniform visual UX standard.

What if there are Multiple Plants?

Multi-plant environments also support system standardization, without this implying leaving any of them behind, thanks to the MES Enterprise solution. This solution takes into account the unique needs of each plant, such as greater flexibility in recipe limits, variability in the quality of raw materials, and different production processes.

The MES Enterprise configuration uses the Model-Driven approach to define models that will be implemented in all the company’s plants. This ensures that each plant adopts the same standards and subsequently adjusts the templates as appropriate in each case. In this way, consistency in the execution of tasks and in data collection is guaranteed, facilitating the meaningful comparison of KPIs between plants and promoting continuous improvement at the enterprise level.

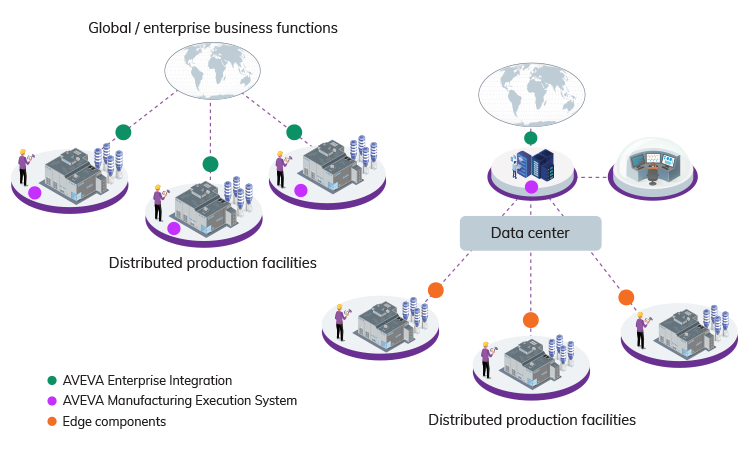

Unlike traditional MES deployments in multiple local sites, the architecture of a centralized MES Enterprise facilitates standardization and significantly reduces IT infrastructure costs, with a corporate data center hosting a single MES for multiple plants.

This centralized system models the physical configuration and unique capabilities of each plant, storing standard templates that govern all operations in the plants.

Building a Solid Foundation for Digital Evolution

In short, the standardization of MES and SCADA systems opens the doors to having a solid foundation for digital evolution:

● Preparation for growth: by standardizing processes, plants prepare for future growth, as it is easier to scale standardized operations than those that are ad hoc or inconsistent.

● Cost savings: the reduced need for duplicate software and hardware, as well as IT resources and subject matter experts to maintain multiple systems, translates into significant savings in infrastructure and ownership.

● Faster product launches: with a centralized MES, the updating of data from R&D, ERP, PLM, and other external systems is automatically synchronized in all connected plants. This accelerates the introduction of new products and allows for a faster response to changes in the market.

● Better supply chain visibility: finally, an enterprise MES facilitates the visualization of multi-site operations and the coordination of the supply chain, which allows companies to plan and manage the supply chain more intelligently, responding to disruptions and changes in demand with greater agility.