EAM: Systems Integration

EAM/CMMS, Becolve Digital's data integration and exchange system, improves efficiency in business operations.

The integration and exchange of data between different business systems allows organizations to improve efficiency in operations. Among these systems is the EAM/CMMS.

Traditionally (and still in many environments), maintenance management systems have been an information silo: isolated systems where no external data transfer occurs within the organization. EAM/CMMS systems were responsible for managing information related to asset maintenance, and rarely exchanged information with external systems; at most, reports were extracted manually to present them to management.

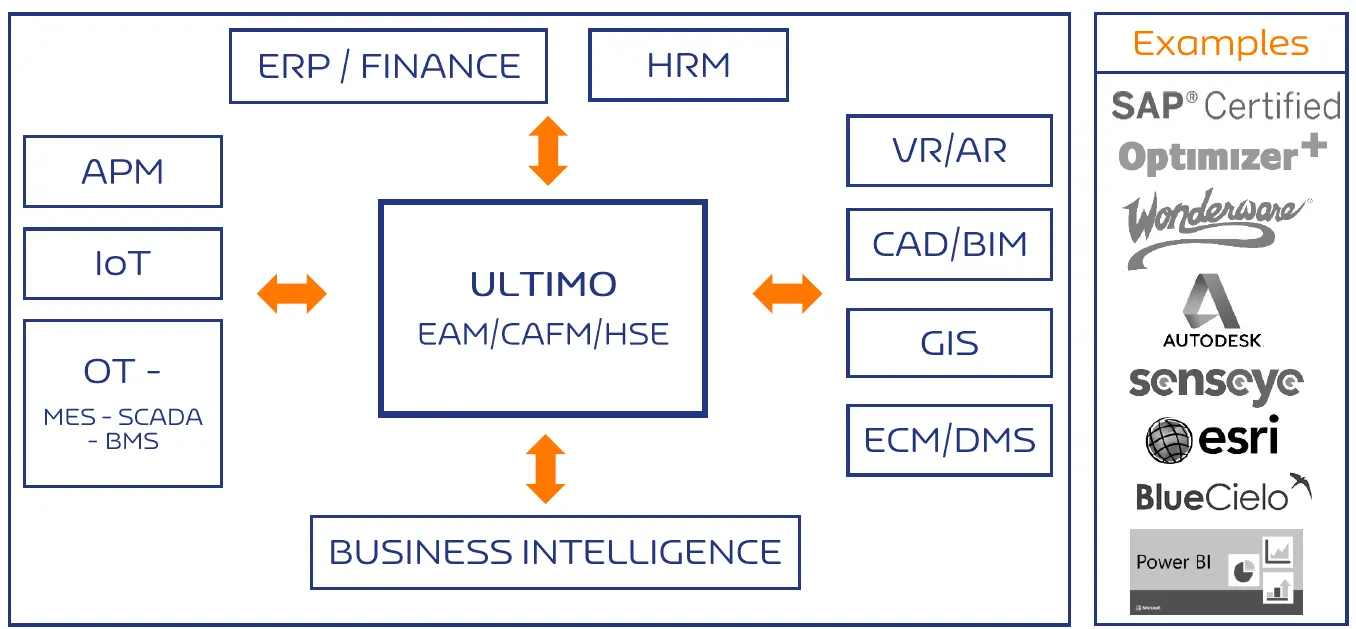

Increasingly, the focus is on having an EAM system that is bidirectionally integrated with the company’s various systems. This allows a fluid communication of relevant data with other systems, allowing to anticipate breakdowns or anomalies and thus speed up decision-making.

To obtain a unified asset management approach, it is important to share reliable and updated information between systems. Below are some examples of integration:

Integration with Control Systems

In this case, a control system is understood as SCADA or IoT devices that can send and manage real-time data. Sharing real-time information with the EAM system allows knowing the current condition of the assets, allowing to apply a better maintenance plan and anticipate possible failures.

From this systems integration, the concept of condition-based maintenance is born. This maintenance strategy is based on the current state of the assets: on indicators that can determine if the asset is about to suffer a breakdown, if it has already broken down, or if it requires maintenance to function optimally again. This type of maintenance is considered a “preventive maintenance” since, through real-time information of different parameters of the asset, more serious breakdowns can be avoided, thus reducing the downtime of these.

If you want to know more, we recommend this post: Intelligent Maintenance: Condition-Based Maintenance

Integration with MES Systems

In the industrial sector, an MES (Manufacturing Execution System) allows us to manage and optimize production activities from the release of the order to the finished products.

The maintenance and production areas are two departments where the work of each often conflicts with the other. Production seeks the maximum availability of the machine to produce, while maintenance aims to guarantee the availability of the asset through preventive maintenance.

Although both areas have the same objective of guaranteeing productivity, they have different points of view, and mostly enter into the dispute of asset availability versus preventive maintenance of it.

It is for this reason that it is vitally important that these two departments work together to have good communication between them, understand the state of production, and schedule the appropriate number of preventive maintenance and when these stops do not affect the most critical orders.

Integration with ERP Systems

ERP (Enterprise Resource Planning) systems are responsible for managing the business resources of different areas: financial resources, manufacturing, supply chain, human resources, and operations.

In the integration of EAM systems with ERP, it is most common to use it for the purchasing department, where it is essential to have all the organization’s costs in a single system and with the detail they require.

The purchasing department usually manages all the purchases of the organization, including maintenance, and it is essential that these two systems have an exchange of information to avoid stock breakage of maintenance items, make urgent purchases, or manage orders to subcontractors.

If you want to know more, we recommend this post: CMMS and ERP Integration.

Integration with GIS Systems

GIS is a geographic information system. The integration of a GIS system with an EAM is usually done especially in companies with a large number of dispersed assets or for the control of assets in motion.

This allows having information on the geographic location of the asset and performing groupings of maintenance work in the same area. In most cases, when working with this architecture, mobile devices are usually used to support field work.

An EAM system with the possibility of integration with different systems is essential, and is often a major deciding factor during the software selection process.

Ultimo EAM offers the option of integration with external systems, through certified standard interfaces and ready-to-use connectors. Ultimo offers integrated email communication, can use several predefined integrations, REST APIs and configure specific workflows for integrations. In addition, it is possible to perform batch imports and exports through the use of predefined Ultimo Business Integration (BI) connectors.

Want to learn more about the integration possibilities with Ultimo?